Blog Post

Basics of Hydraulic Flow

Aug. 21, 2019

Hydraulic flow can be defined as the volume of fluid that flows through a surface area during a specific period of time. Sounds straightforward, right? Well, it turns out there’s more to it than meets the eye. In this post, we will explain the basics and offer several solutions to overcome the challenges you may have faced in your applications.

The Situation

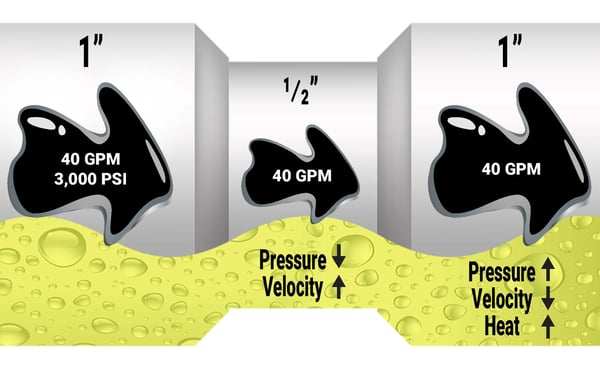

Let’s say you’re trying to connect two pipes of different sizes. One pipe has a 1-inch diameter; the other has a ½-inch diameter. There are a few basic laws of fluid dynamics you should consider first: The amount of liquid flowing from the larger pipe to the smaller pipe will stay the same. At the same time, the pressure in the system will drop and the speed at which the liquid is traveling--its velocity--will increase.

Okay, so now let’s say you need to reverse the flow: you’d like to pump liquid from the smaller pipe to the larger one. In that case, the rate of flow--gallons per minute--remains the same, pressure within the system increases somewhat, but now the velocity of the fluid decreases, while heat within the line goes up. Got all that?

Complicating Factors

Ah, but there’s something else in the scenario we didn’t consider. In order to join the pipes or hoses together, you’ll likely need to use a quick disconnect of some sort. When you do that, valves within the quick disconnects influence the fluid dynamics of the entire system. As a result, the pressure within the line will drop, and heat will increase due to turbulence as well as the restricted flow. That rule applies not only when connecting pipes or hoses of different sizes but also when connecting pipes or hoses of equal size.

Hydraulic systems require a certain amount of flow to run efficiently and effectively, so deciding which type of quick disconnects to use is vital. The heat created from the turbulence of fluid running through quick disconnects can really limit the performance of a hydraulic system. Use the wrong size or style of quick disconnect? You might also risk limiting the performance of the system or even damaging it.

The Solution

In order to ensure the least amount of flow obstruction, Dixon designed several types of valves that allow for better flow and less pressure drop. First, our dual opposing retention spheres (DORS) valve design in our flat face HT-Series (and VEP-Series) hydraulic quick disconnects helps minimize heat and pressure drop versus competitive products in the market. See the comparison between our DORS valve and our competitor’s valve below.

Cutaway of Dixon’s DORS valve indicates a pressure drop of 10.93 PSI. The color scale represents pressure in PSI. Click the video above to watch a demonstration.

Cutaway of a competitor’s valve indicates a pressure drop of 24.71 PSI. The competitor’s valve has a larger pressure drop compared to the outlet of Dixon’s DORS valve. The color scale represents pressure in PSI. Click the video above to watch a demonstration.

W-Series

Another innovative quick disconnect series for hydraulic systems is Dixon’s W-Series, also known as the “Wingstyle” series. There are major differences in design between the majority of valves on the market valve guide and Dixon’s hybrid valve guide. Using other companies' valves will cause a drop in pressure and possibly flow rate due to flow obstruction and redirection of the flow path. Using Dixon’s W-Series valves will provide a smoother flow path, lead to a smaller drop in pressure, and generate less heat.

Cutaway of Dixon's hybrid valve. Click the video above to watch a demonstration.

Cutaway of a competitor’s non-hybrid valve. Click the video above to watch a demonstration.

E-Series/TD-Series

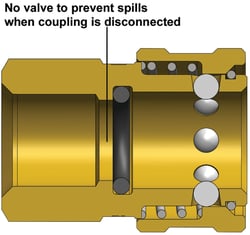

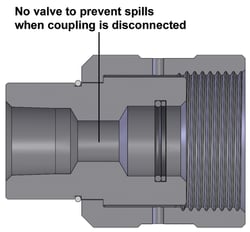

If your application requires a minimal decrease in pressure in order to maintain high pressure and flow (such as in a power washer or similar system) consider the Dixon E-Series or TD-Series. These two series lack valves entirely, ensuring minimal flow obstruction within the system. With no valving to cause a flow obstruction, the E-Series and TD-Series provides up to twice the flow rate that the HT-Series or W-Series can provide for a given hose size. For this reason, the E-Series is frequently used in applications that require high flow, like pressure washing. The TD-Series offers similar benefits but is designed to withstand higher pressures than the E-Series. The trade-off to these high-flow quick couplings is that there is no valve to prevent spills when the coupling is disconnected. As a result, use of these couplings is limited to non-hazardous media.

E-Series

TD-Series

Want to learn more? If you’d like additional information on any of the products mentioned above, please contact Dixon.

![]()